Adapting to Last-Minute Changes in Semiconductor Fab Clean Rooms Design

Our customer, a leading company in the semiconductor industry, encountered an unexpected challenge through the engineering phases of his project: the cleanroom, integral to his semiconductor wafer fab, had to be relocated at the last minute. The initial cleanroom design was meticulously crafted to fit a specific space, achieving a specific scope of work with tight performance criterium. However, due to unforeseen circumstances, the entire project needed to be adapted to a new location without altering the original purpose and deadline.

This sudden change presented several obstacles. The new space had different dimensions and structural constraints, requiring a complete redesign of the cleanroom layout. Additionally, the client needed assurances that the new design would maintain compliance with all semiconductor clean room standards, including those governing air purity, temperature, and humidity control, which are critical for the delicate processes involved in semiconductor manufacturing.

MECART’s Modular System for Semiconductor Clean Rooms

MECART’s innovative modular system was the key to overcoming these challenges. The system is built around standardized components that can be quickly customized to fit unique requirements, making it ideally suited for semiconductor processes that demand flexibility and speed. This approach allowed MECART to rapidly pivot and redesign the cleanroom to accommodate the new space while still adhering to the rigorous standards required for semiconductor wafer fab environments.

A standout feature of the MECART cleanroom system is its self-supporting structure. Unlike traditional cleanrooms, which often require extensive support from the host building itself—such as ceiling rods or structural reinforcements—the MECART cleanroom is entirely self-sustaining. This means the building didn’t need to be modified or reinforced to accommodate the clean room, allowing for greater flexibility in its placement and reducing overall project complexity.

Additionally, the new location allowed for HVAC system could be installed directly on top of the MECART cleanroom, streamlining the installation process and ensuring optimal airflow and filtration.

One of the aspects the customer particularly appreciated was the ability to access the HVAC filters from outside the cleanroom. This design feature minimizes the risk of contamination by allowing maintenance personnel to change filters without having to enter the cleanroom, thereby avoiding the need to gown up. This not only reduces downtime but also enhances the overall efficiency and cleanliness of the semiconductor manufacturing process.

A High-Performance Cleanroom for Semiconductor Wafer Fab

The completed project resulted in a state-of-the-art cleanroom specifically designed for semiconductor wafer fab processes. The cleanroom not only met but exceeded all necessary semiconductor clean room requirements, providing a pristine environment with controlled levels of particulate contamination, temperature, and humidity. This environment is essential for the high-precision work required in semiconductor manufacturing, where even the smallest deviation can impact product quality.

The cleanroom was also equipped with advanced semiconductor wafer fab equipment, integrated seamlessly into the layout to optimize workflow and efficiency. MECART’s modular design allowed for easy installation, clean service integration and future scalability/serviceability with removable walls, giving the client the flexibility to expand or modify the cleanroom as their semiconductor production needs evolve.

Meeting Semiconductor Clean Room Standards

Adaptability: MECART’s modular system proved crucial in allowing for rapid design changes, ensuring the cleanroom could be tailored to a new space without compromising on semiconductor clean room standards.

Efficiency: The ability to quickly re-engineer and install the clean room, despite a significant change in location, underscores MECART’s capacity to deliver on time without sacrificing quality.

Self-Sufficiency: The cleanroom’s self-supporting structure eliminated the need for host building modifications, and the HVAC system could be placed directly on top of the cleanroom, simplifying the installation process.

Contamination Control: The external access to HVAC filters was a significant advantage, reducing the risk of contamination and minimizing downtime by allowing maintenance without the need for gowned maintenance workers.

In summary, this case study highlights MECART’s proficiency in delivering tailored semiconductor clean rooms that meet the highest standards of the industry.

The project serves as a testament to MECART’s ability to adapt to unexpected challenges while maintaining a commitment to quality and timeliness, ensuring that their clients’ production schedules and quality standards are never compromised.

DID YOU KNOW?

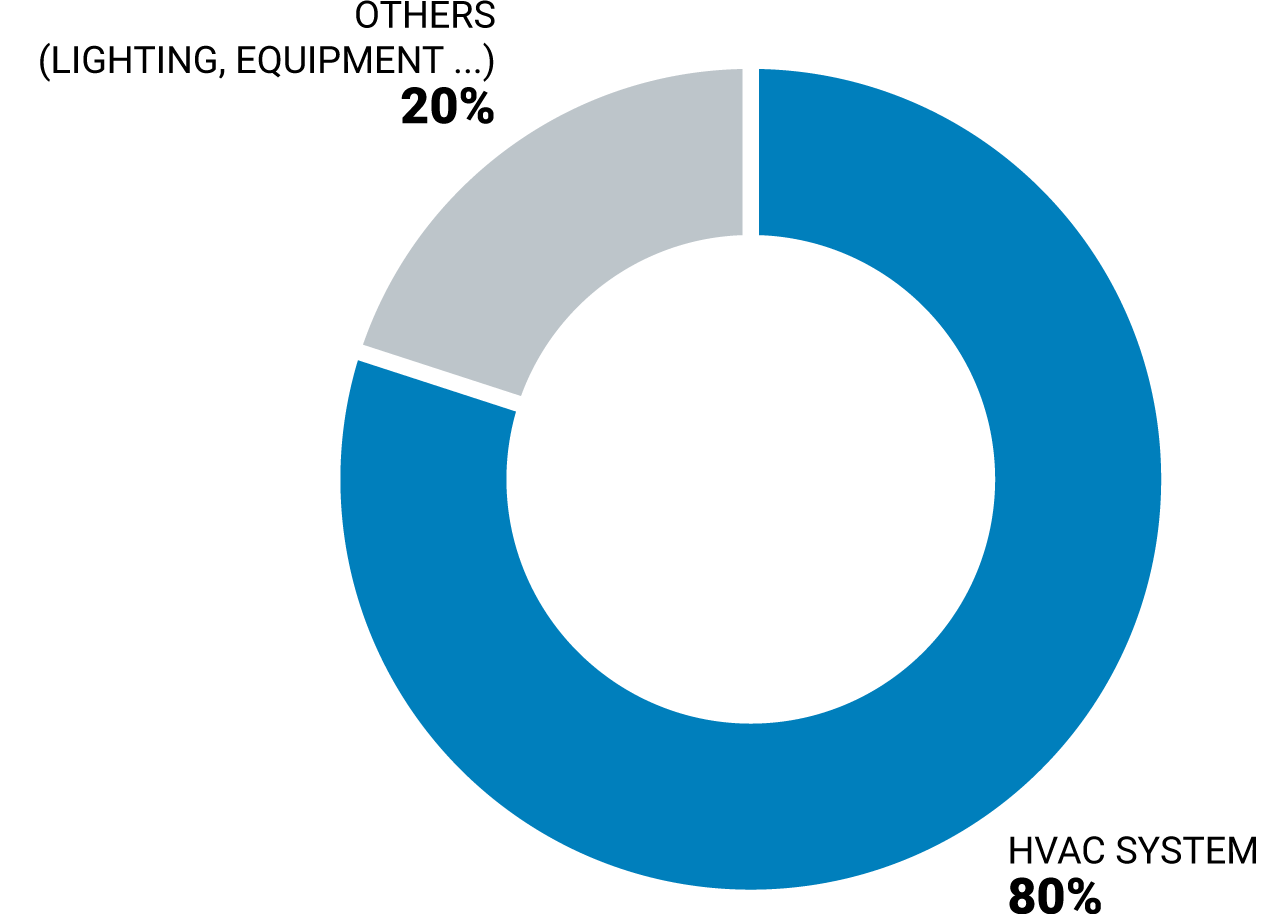

Did you know that, on average, the heating, ventilation, and air conditioning (HVAC) system accounts for approximately 80% of the total energy consumption in a cleanroom?

There are ways to lower these expenses. Find out from the MECART specialists what measures can be taken to reduce these expenses.

Contact us for semiconductor cleanroom solutions