HD Compounding Cleanroom

(sterile and non-sterile)

360° Virtual Tour

Get a virtual tour of one of our hazardous drug compounding cleanrooms!

The USP General Chapter 800 (USP-800) regarding the safe handling of hazardous drugs will come into effect in December 2019. Are you ready? Our client is!

This pharmacy will be offering hazardous drug compounding services to its customers in a brand-new facility, which also include a compliant HD cleanroom. The entire Mecart compounding cleanroom is approximately 700 sq. ft.

Book a call to discuss your project

How to Navigate through the Virtual Tour of the Cleanroom

There are two ways of navigating through the cleanroom. You can move inside by clicking on the arrows or go directly to a given room using the menu located on the top, left-hand corner.

If you have virtual reality (VR) glasses, you can use them for an even better immersive experience. Put your glasses on and click on the headset icon, which is situated at the bottom left-hand corner.

To travel from one room to another, align the target with an arrow and don’t move for a few seconds.

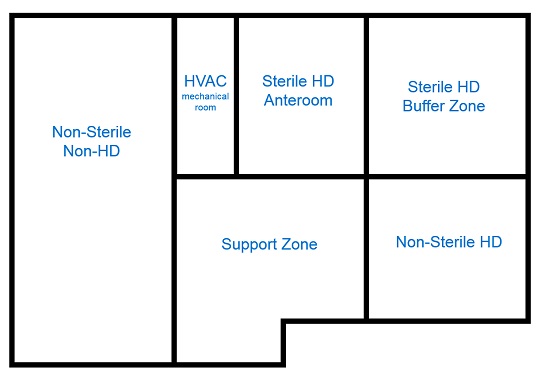

The HD Compounding Facility Layout

The cleanroom is located in Quebec, Canada and follows OPQ, NAPRA and USP-800 standards. However, the layout is somewhat different from the one requested by USP-800 in the United States.

Patients sitting in the waiting area of the pharmacy can see inside the non-sterile HD cleanroom.

The cleanroom entry is accessible from the back of the office. It opens to the non-sterile, non-HD compounding space. The HVAC mechanical room is accessible from the back of the non-sterile non-HD space for easy maintenance. Workers can then enter the Support Zone.

From there, the first door leads to the HD Anteroom, followed by the Sterile HD cleanroom (buffer zone) where the NuAire Biological Safety Cabinet (BSC) Class II type B2 is located.

The second door leads to the Non-Sterile HD cleanroom with two C-PEC hoods (Class I containment ventilated enclosures).

This layout is specific to the pharmacy’s needs. A typical layout varies a little. For instance, the cleanroom entry door is usually in the Support Zone. Many layouts are possible depending on the compounder’s needs—as long as they follow the USP-797 and 800 guidelines (and USP-795, if applicable).

Mecart HD Compounding Facility Services

Mecart supplied both the cleanroom shell (walls, ceilings, doors, windows, etc.) and the HVAC system (positive and negative pressure, air returns, exterior exhaust, duct, monitoring system, etc.).

The HVAC system is definitely the most challenging component when engineering a USP-800 HD compounding facility. First, the HVAC system must achieve negative pressurization. It also requires dedicated exhaust ductwork to evacuate the potentially contaminated air to the outside of the building—all while minimizing the routing of exhaust equipment.

What is USP-800?

The reasoning behind USP-800 is to protect workers handling hazardous drugs (both non-sterile and sterile) and the environment in which the drugs are being handled. Hazardous drugs include those used for cancer chemotherapy, antiviral drugs, hormones, some bioengineered drugs, and other miscellaneous drugs.

Need a cleanroom?

Give us a call or learn more about our solutions for compounding pharmacies.