Cost of a Cleanroom per Square Foot – How much does a Modular Cleanroom Cost

Why We Can’t Provide a Cleanroom Cost per Square Foot Without Preliminary Engineering?

– Verifying assumptions and clarifying potential misconceptions

– Identifying opportunities to optimize your design and eliminate unnecessary expenses

Why you should run away if a supplier gives you a none-reflected price per square foot

Download the cleanroom brochure

The brochure details MECART’s engineering capabilities, the MECART cleanroom features along with data sheets and case studies.

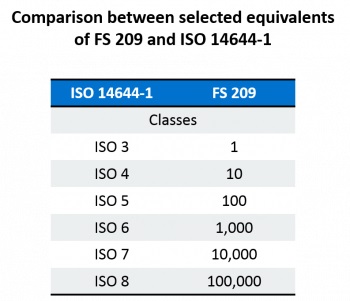

1) Cleanroom Classification

An ISO 6 and an ISO 8 cleanroom are not the same price per square foot. A non-hazardous sterile compounding cleanroom or a hazardous sterile compounding cleanroom in negative pressure are not the same price.

Why?

- First, the amount of air is different in an ISO 6 and in an ISO 8. Remember the air is 100 times cleaner in an ISO 6 than in an ISO8. Hence the HVAC system must be capable of conditioning more than double the air. A cleanroom isn’t simply wall panels and ceilings. The heart of the cleanroom is the air treatment system (HVAC) which can represent between ¼ to half the price of the cleanroom.

- In addition to the HVAC system, the cleanroom classification will also influence the required amount of enclosed rooms. For example, you can enter an ISO 8 cleanroom directly from an uncontrolled environment. On the other hand, you will need at least one airlock (recommendation is 2) before entering an ISO 6 environment. This adds wall partitions, doors, ceilings… and thus costs.

2) The Size

A fundamental principle applies to cleanroom construction: the larger the room, the lower the cost per square foot. This phenomenon, known as economy of scale, means that while the total cost increases with size, the cost per square foot decreases.

3) Using a fume hood, biosafety cabinet

If your fume hood exhausts air to the exterior of the building, you will need to replace the exhausted air with fresh air. This fresh air will need to be conditioned (temperature and relative humidity). This requires a larger air make up or WHERE air handling unit.

4) Monitoring System

For most regulations, you must have a record of the conditions within the cleanroom. Do you mind writing everything down by hand or do you want the system to record everything for you? Monitoring system costs range from $500 to $20,000 +.

5) The space and location where it will be installed

Undoubtedly, the distance from the manufacturing facility to your site will influence the price.

If installation is included in the price per square foot, the cleanroom manufacturer must estimate the time and level of difficulty of installation. In order to do so, we must know everything about the location.

What is the space like?

- Are there obstacles?

- What is the height below the trusses?

- Are there any columns?

- What is the existing floor, is it concrete? Is it leveled?

- What power is available? (1 phase, 3 phases)

- How accessible is the available space

We once shipped a cleanroom to a 16th floor in downtown Toronto. We had to close the street, get an escort, and a crane to lift up the panels to the 16th floor and then pass them through the windows. See for yourself in this video. This is an extreme situation but you can imagine that in this particular project versus a simple installation in an empty warehouse, there is a major price difference.

Also, what is the temperature/HR control like in this space in the building, is it heated in winter and conditioned in summer? Otherwise the HVAC will have to work harder to keep the environment controlled.

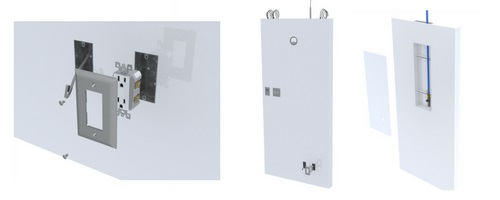

6) Utilities and access panels within the walls

What services will your process require? Plain empty cleanroom wall panels are cheaper than utilities ready ones. If you need 3 power outlets vs 40, we are not talking about the same price.

Utilities include power receptacle (120 v, 208, 240, 600…), plumbing (hot/cold water, deionized water), compressed air, etc.

7) The High-End Look

There are different models of air return grilles, windows, doors, etc.

Doors & Windows

The number, the size and the type of windows impact the cost per square foot. So does the type and number of doors.

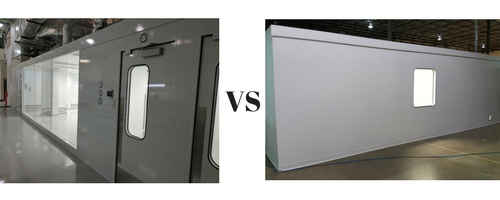

Full Flush or Semi-Flush

The price will also differ if you choose full flush or semi-flush mount windows.

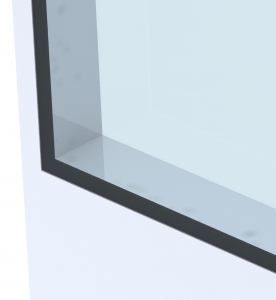

FULLY FLUSH MOUNT WINDOW

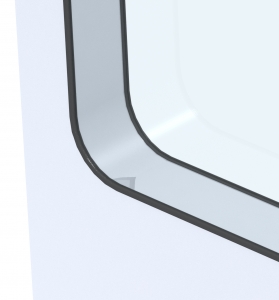

Semi-Flush Mount Window

Full Flush or Semi-Flush Air Return Grille

Same thing with the magnetized air return grille for a fully flush option.

Lighting System

The required level of lighting will also affect the price, whether you want the cleanroom to achieve 300 to 1200 lux.

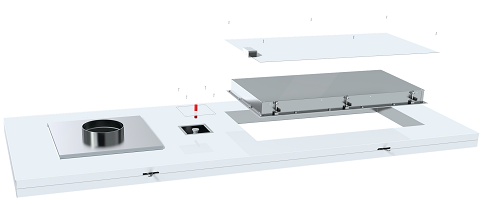

There are also various lighting system options, ranging from the standard lighting to the full flush lighting accessible via the roof, meaning you can change the lights from outside the clean envelope.