Clean Room Classifications

(ISO 8, ISO 7, ISO 6, ISO 5)

Clean Room Classifications

Clean rooms are classified according to the cleanliness level of the air inside the controlled environment. The clean room class is the level of cleanliness the room complies with, according to the quantity and size of particles per cubic meters of air. The primary authority in the US and Canada is the ISO classification system ISO 14644-1.

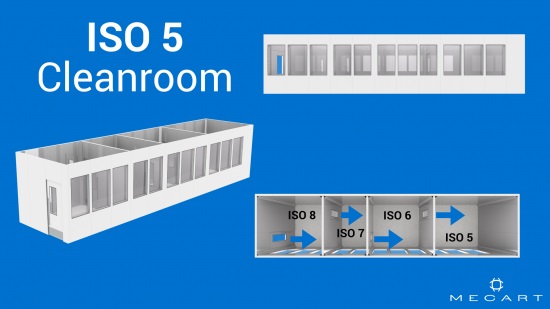

This ISO standard includes these clean room classes : ISO 1, ISO 2, ISO 3, ISO 4, ISO 5, ISO 6, ISO 7, ISO 8 and ISO 9. ISO 1 is the “cleanest” class and ISO 9 is the “dirtiest” class. Even if it’s classified as the “dirtiest” class, the ISO 9 clean room environment is cleaner than a regular room.

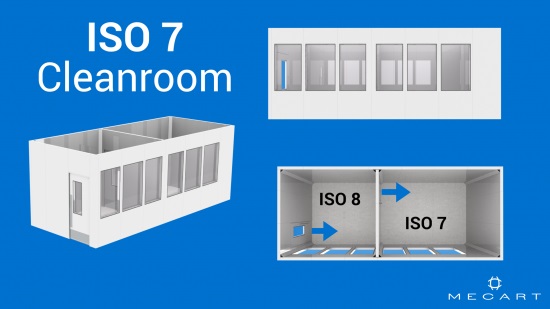

The most common ISO clean room classes are ISO 7 and ISO 8. The Federal Standard 209 ( FS 209E ) equivalent for these ISO classes are Class 10,000 and Class 100 000.

The old Federal Standard 209E ( FS 209E ) includes these clean room classes : Class 100,000; Class 10,000; Class 1,000; Class 100; Class 10; Class 1. This standard was replaced in 1999 by ISO-14644-1. It was withdrawn in 2001, but it is still widely used.

Clean rooms must also follow industry-specific and international standards. For example, EU GMP (A-B-C-D), applies to pharmaceutical products and USP (795, 797 and 800) to compounding pharmacies.

You might also like this article —>How Classification Impacts your Cleanroom Design

Want to learn more about Clean Rooms? —>What is a Clean room?

Download the cleanroom brochure

The brochure details MECART’s engineering capabilities, the MECART cleanroom features along with data sheets and case studies.

| ISO 14644-1 | FS 209E |

|---|---|

| ISO 3 | Class 1 |

| ISO 4 | Class 10 |

| ISO 5 | Class 100 |

| ISO 6 | Class 1,000 |

| ISO 7 | Class 10,000 |

| ISO 8 | Class 100,000 |

Clean room classification particle concentration

The basis of clean room standards is the micrometer, or micron for short (µm), which is the size of the particles to be filtered. As stated before, clean rooms are classified by how clean the air is, according to the number of particles and size of particles per volume of air. The clean room classification table below shows the maximum concentration limits (particles/m3 of air) for particles equal to and larger than the considered sizes shown.

Some classifications do not require certain particle sizes to be tested because the respective concentrations are too low or too high to be tested, but they should not be zero.

| ISO Class | Maximum Particles/m3 | Particles/ft3 | FS 209E Equivalent | |||||

|---|---|---|---|---|---|---|---|---|

| ≥0.1µm | ≥0.2µm | ≥0.3µm | ≥0.5µm | ≥1µm | ≥5µm | ≥0.5µm | ||

| ISO 1 | 10 | |||||||

| ISO 2 | 100 | 24 | 10 | |||||

| ISO 3 | 1,000 | 237 | 102 | 35 | 1 | Class 1 | ||

| ISO 4 | 10,000 | 2,370 | 1,020 | 352 | 83 | 10 | Class 10 | |

| ISO 5 | 100,000 | 23,700 | 10,200 | 3,520 | 832 | 29 | 100 | Class 100 |

| ISO 6 | 1,000,000 | 237,000 | 102,000 | 35,200 | 8,320 | 293 | 1,000 | Class 1,000 |

| ISO 7 | 352,000 | 83,200 | 2,930 | 10,000 | Class 10,000 | |||

| ISO 8 | 3,520,000 | 832,000 | 29,300 | 100,000 | Class 100,000 | |||

| ISO 9 | 35,200,000 | 8,320,000 | 293,000 | |||||

** Old FS 209E classes were calculated in particles per cubic foot, whereas ISO classes are in cubic meter of air.

| ISO Class | Maximum Particles/m3 | Particles/ft3 | FS 209E Equivalent | |||||

|---|---|---|---|---|---|---|---|---|

| ≥0.1µm | ≥0.2µm | ≥0.3µm | ≥0.5µm | ≥1µm | ≥5µm | ≥0.5µm | ||

| ISO 7 | 352,000 | 83,200 | 2,930 | 10,000 | Class 10,000 | |||

For ISO 7, particles smaller than 0.5 microns (≥0.1 µm, ≥0.2 µm, ≥0.3 µm) are not taken into consideration. The concentration of particles of ≥0.5 µm and above should be below 352,000, for particles of 1 micron and above 83,200 or lower and for particles of 5 microns and above 2,930 or lower.

Cleanroom classification and air changes per hour

Air cleanliness is achieved by passing the air through HEPA filters using flow principles such as laminar flow. The more often the air passes through the HEPA filters, the fewer particles are left in the room air. The volume of air filtered in one hour divided by the volume of the room gives the number of air changes per hour.

| ISO Class | Average number of air changes per hour |

|---|---|

| ISO 5 | 240–360 (unidirectional air flow) |

| ISO 6 | 90–180 |

| ISO 7 | 30–60 |

| ISO 8 | 10–25 |

| Conventional building | 2–4 |

The above-suggested air changes per hour are only a design rule of thumb. They should be computed by an HVAC clean room expert, as many aspects must be taken into consideration, such as the size of the room, the number of people in the room, the equipment in the room, the processes involved, the heat gain, etc.

Disclaimer

This article will help you understand the basic differences between an ISO 5, ISO 6, ISO 7 and ISO 8 clean room as per ISO 14644. Please note that this information is only provided for educational purposes.

The definitions in this article are oversimplified in order to assist with understanding. This article will not help you decide which clean room classification you must reach. If help is needed in this respect, seek the advice of an expert in your industry (pharmaceutical, medical devices, sterile compounding, electronics, etc.).

Turnkey Design-Build & Partnerships

We can Design-Build-Install and Commission your cleanroom or we can partner with other professionals that your are currently working with!