Home / Learning center / Top 10 Cleanroom Projects from 2021

Top 10 Cleanroom Projects from 2021

With 2021 now behind us, we prepared a recap of some of last year’s cleanroom projects.

1. Vaccine Plant and Biologics Manufacturing Cleanrooms

The pandemic has demonstrated the shortcomings of not having access to locally manufactured vaccines, which creates a dependence on foreign vaccines, which may be challenging to obtain for financial reasons or political advantage. Many vaccine manufacturing factories are being built across Canada to be fully prepared to address the next pandemic or to support the global vaccination efforts being deployed. This project is no different.

The vaccine plant totals 14,000 square feet of clean room space and consists of a media preparation room, a packaging room, two subculture rooms, a buffer preparation room, as well as some personnel airlocks (PAL) and material airlocks (MAL). The vaccine factory’s clean rooms comply with good manufacturing practices (cGMP).

2. Medical Injection Molding Cleanroom for Vaccine Components

Project summary:

- Medical Device Cleanroom

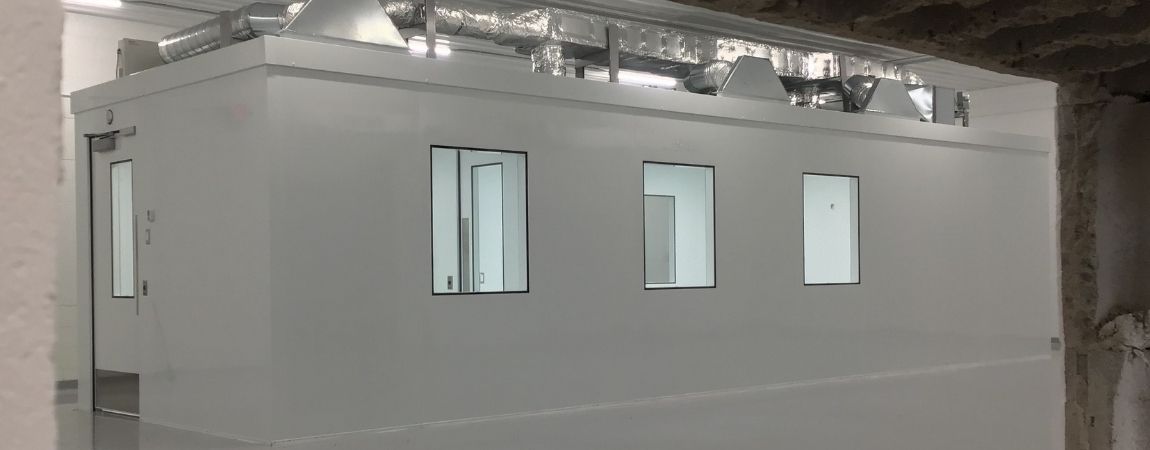

- 18 000 square feet

- Stand-alone and freestanding

- GMP cleanroom facility

- ISO 7 for the main room and ISO 8 for gowning room

This 18 000 foot² cleanroom expands an already existing facility that manufactures plastic components for vaccine manufacturing for a Fortune 100 company. The pandemic created a massive demand for vaccines, increasing demand for all the components needed to manufacture and distribute vaccines.

The cleanroom is divided into 5 rooms, including a molding room, quality assurance (QA) lab, gowning room, and multiple material airlocks (MAL) and personnel airlocks (PAL). All rooms have elevated airflow to support GMP requirements for manufacturing medical devices.

Read this Medical Device Cleanroom Case Study

3. Cleanroom Laboratories for CDMO Specialized in Nucleic Acid Products

This Canadian Contract Development and Manufacturing Organization (CDMO) needed multiple cleanroom labs to support their client’s need for nucleic acid products such as plasmid DNA and mRNA cap analogs.

This biotech company needed 3 cleanroom laboratory spaces plus a filling room. All laboratories are ISO 7 cleanrooms, while the filling room is an ISO 6 for the more stringent fill/finish operations. The cleanroom suite also includes a few gowning rooms kept at an ISO 8 cleanliness level. The whole cleanroom project covers 2309 sq. ft. inside the client’s main building.

4.GMP Biotech Production Cleanroom for Allergy Treatments

- Project Summary:Pre-clinical stage pharmaceutical company

- Production and analytic suite

- cGMP (Grade B, C, and D)

- ISO 7 & ISO 8

- 1 000 sq.ft.

- Custom HVAC

This Canadian pre-clinical stage pharmaceutical company needed a new cleanroom environment for upscaling the production of its unique vaccine platform. The cleanroom complies with Good Manufacturing Practices (cGMP) and is divided into three zones.

The 3 areas include Grade B, Grade C, and Grade D according to GMP requirements, which can be translated to ISO 7 and ISO 8 cleanroom spaces under the ISO cleanroom regulations. (Grade B is sometimes ISO 5, when not in operation)

The nearly 1 000-square-foot modular cleanroom includes Mecart’s custom HVAC system to obtain the required cleanliness levels. The cleanroom panels are also designed for utilities and services integration (water, air, electricity, etc.)

Read this Biotech Cleanroom Case Study

5. USP 797 Sterile Compounding Cleanroom for Specialty Pharmacy

This specialty pharmacy needed a new cleanroom fully customized to its environment. The company offers specialty pharmaceutical services to patients with rare or complicated health problems.

Specialty medicines are frequently big, injectable, protein-based compounds manufactured by a biotechnology process, although they can also be tiny molecules produced via regular pharmaceutical production processes. In both cases, a rigorous cleanroom environment is mandatory for the sterile compounding of those specialty pharmaceuticals.

Mecart delivered a cleanroom to meet all their needs. The 180-square-foot cleanroom is divided into 2 areas, an ISO 7 cleanroom space with an adjoining ISO 8 anteroom. The cleanroom is compliant with USP 797 guidelines: Pharmaceutical Compounding – Sterile Preparations.

6. CGMP & BIOTECH CLEANROOM FOR STEM CELL MANUFACTURING – THERANOSTICS

Cleanroom Summary:

- Square Footage Range: 300 sq. ft.

- Location: Eau Claire, Wisconsin

- Industry/Application: Biotechnology/Pharma/Theranostics

- Cleanroom: ISO 7/Class 10,000 & ISO 8 Gowning Room

- cGMP compliant

This biotechnology company needed a new cleanroom environment for manufacturing patient-specific iPS cell lines used for oncology research and theranostic treatments.

The cleanroom has a surface area of 300 square feet and is divided into 3 rooms. The cleanroom lab is an ISO 7 room, and the background zone is an ISO 8 anteroom. The mechanical room is adjacent to the cleanroom.

Read this cGMP Theranostics Cleanroom Case Study

7. Cleanrooms for early stage biomanufacturing and bioinformatics

This company develops products at the crossroads between the biotechnology and medical device industries to enable rapid screening and prototyping of new biological materials for drug discovery.

To achieve this particular feature, they needed new cleanroom space for manufacturing purposes. They contacted Mecart to purchase a 1025 square foot clean room that would be divided into two separate areas.

The main cleanroom offers an ISO 7 level of cleanliness, while the smaller gowning room is maintained at an ISO 8 level. A ventilated passthrough was also included in the cleanroom project.

8. NAPRA Compliant Cleanroom Pharmacy

This Ontario-based healthcare and pharmaceutical company needed a new sterile compounding pharmacy. The clean room environment is divided into 2 spaces: a non-hazardous ISO 7 cleanroom and an ISO 8 anteroom.

The sterile compounding cleanroom is 450 square feet and includes a pass-through with an interlocking system. The stand-alone cleanroom is not fixed to the already existing structure of the building and is entirely independent. Clients often choose either a pharma-grade welded vinyl floor, or epoxy – like the beautiful blue floor shown in this photo.

In a nutshell, the sterile compounding pharmacy consists of:

- An ISO 7 cleanroom with an ISO 8 anteroom

- 450 sq. ft. of cleanroom space

- Flush finish for walls, windows, and ceiling

- Easily cleanable

- NAPRA/USP

- A sink, a monitoring system, and pass-through

9. ISO 8 Sampling and Packaging Room for a Biopharma CDMO

Here is a summary of this cleanroom project:

- Industry: Biopharma/CDMO

- Cleanroom Class: ISO 8

- Dimension: 750 sq. ft.

- Location: Research Triangle Park (RTP), North Carolina

- Application: Packaging and Sampling Room for Biopharma Products

The North Carolina-based new cleanroom has a footprint of 750 square feet and is divided into 3 rooms. The cleanroom space will be dedicated to packaging and sampling operations for biopharma products.

The packaging room also includes 4 total doors: 2 regular cleanroom doors and 2 sliding doors, with flush finish windows and automatic, touch-free door operators. The doors are also equipped with an interlocking system to meet the cGMP cleanroom requirements and regulations. We can see both types of entries in the picture.

The cleanroom is equipped with a custom HVAC and AHU system. The HVAC system will achieve 25 air changes per hour (ACH) to maintain the cleanroom to an ISO 8 level.

10. Compounding Cleanroom for IV Solutions and Chemotherapy (USP 797, USP 800)

Project Summary:

- Industry: Compounding Pharmacy

- Square footage: 310 square feet (divided into 3 rooms)

- Cleanroom Class: USP 797 & USP 800

- Layout: ISO 7 Buffer and Chemo rooms + ISO 7 Anteroom

- Location: Maine, USA

Maine offers high-quality hospital care, and this client is a great example. The hospital provides various healthcare treatments that benefit the rural population and many tourists every year. When a cancer diagnosis is given, often patients need to travel far from home to receive cancer treatments. The same challenge is also a burden for some patients with blood disorders and other diseases that require transfusions.

To resolve this, our client decided to offer oncology services to their long list of treatments. They needed USP 797 and USP 800 cleanrooms to compound hazardous drugs and sterile preparation for high-quality cancer care. The 310 ft2 clean room area is divided into 3 rooms: an ISO 7 anteroom and ISO 7 IV solutions cleanroom and chemo room.

Read the Full Case StudyLET US ADVISE YOU ABOUT OUR CLEANROOM OPTIONS

We’ll present a solution matching your needs and budget!