A Complex Challenge: Engineering a Cutting-Edge Cell Therapy Suite

The client embarked on a project to establish a cell and gene therapy facility. This ambitious undertaking required a cleanroom supporting advanced research and manufacturing processes, including CAR-T cell therapies and other innovative treatments. The project presented several key challenges:

- Limited Overhead Space: The cleanroom was to be installed within an existing building with limited overhead clearance, making it difficult to accommodate the complex HVAC and filtration systems required for ISO 7 and 8 classifications.

- Stringent cGMP Requirements: The facility needed to comply with strict cGMP regulations for cell therapy manufacturing, demanding meticulous attention to detail in design, construction, and validation.

- Integration with Existing Infrastructure: The cleanroom had to be seamlessly integrated with the existing building infrastructure, including utilities, fire suppression systems, and other building services.

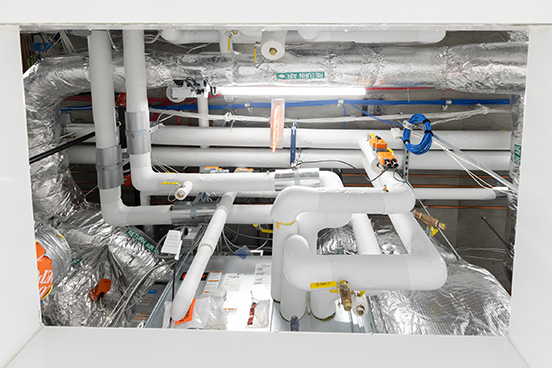

These three images showcase the intricate ceiling design of the cell therapy cleanroom, featuring a custom-built access hatch. This hatch provides convenient access to essential equipment, such as HVAC components and filtration systems, facilitating maintenance and ensuring optimal cleanroom performance. MECART’s meticulous planning and attention to detail in designing such access points streamline maintenance procedures and minimize disruption to critical research activities.

This project showcased the delivery of a high-performance cleanroom that meets the client’s requirements. Our team’s expertise in cleanroom design, combined with advanced BIM coordination and modular construction techniques, ensured the successful completion of this vital facility.

MECART’s Solution: Innovative Design and Seamless Execution

MECART’s modular cleanroom system proved to be the ideal solution for this cleanroom project. Our engineers developed a custom design that addressed the unique challenges of the facility:

- Optimized Ventilation System: To overcome the limited overhead space, MECART designed a sophisticated ventilation system with nine strategically placed air handling units (AHUs). This system ensured proper airflow, temperature, and humidity control while minimizing the risk of cross-contamination between different cleanroom areas.

- BIM Coordination: Our team utilized Building Information Modeling (BIM) to coordinate the complex network of ductwork, piping, and electrical systems within the limited ceiling space. This collaborative approach ensured that all building services were seamlessly integrated and avoided conflicts during construction.

- Modular Construction: MECART’s modular cleanroom system allowed for efficient construction and minimized disruption to the existing research facility. The modular components were prefabricated off-site and then quickly assembled on-site, reducing construction time and costs.

- Compliance with cGMP: our engineers’s expertise in cGMP cleanroom design ensured that the facility met all regulatory requirements for cell therapy manufacturing. The cleanroom was designed with features such as unidirectional airflow, HEPA filtration, and controlled access to maintain the highest levels of cleanliness and sterility.

Results: A State-of-the-Art Facility for Cell Therapy Innovation

The completed cleanroom provides a state-of-the-art environment for cell and gene therapy research and manufacturing. The facility empowers researchers to develop and translate therapies into clinical applications, offering hope to patients with a range of life-threatening conditions. The cleanroom’s key benefits include:

- Enhanced Research Capabilities: The facility provides researchers with the tools and resources they need to conduct cutting-edge research in cell and gene therapy.

- Increased Efficiency: The modular design and optimized workflow enhance the efficiency of research and manufacturing processes.

- Future Scalability: The modular cleanroom system allows for future expansion or modification as research needs evolve.

Partner with MECART for your Cleanroom needs